Ble Based

Yard Management

A Yard Management System (YMS) is software that manages and tracks traffic coming into and within a site such as a distribution centre yard, factory facility or container terminal.

How a YMS can Help:

A YMS will optimize the drivers' tasks, help prevent double moves, streamline communication and eliminate hunting for trailers in the yard.

If your yard drivers are spending valuable time hunting for misplaced trailers, moving the same trailer multiple times and/or the operation is continually waiting on yard drivers to either remove or bring in trailers, you have a good case for implementing a YMS. One of the largest costs of operating your yard is the driver. When productivity slips due to inefficient or non-existent planning, that driver is overworked and it looks like you'll need another person doing that job.

With a YMS you can enforce best practices so that trailers are where they are supposed to be, and manual counting will be a thing of the past.

If staff are out in the yard doing trailer inventory several times a day, they are wasting valuable time and collecting information that is immediately out of date.

A best-of-breed YMS requires a thorough planning process, taking into account business objectives and constraints and building operational rules that will optimize labour and asset utilization.

A lack of planning means that activities are haphazard, nobody takes responsibility and there is a general lack of visibility into activities and trailer locations.

A YMS will allow for automatic check-in via mobile device, and will direct drivers to leave their trailer in an easy-to-find and logical location, thereby helping to encourage good practices.

Manual in and out processes are slowing things down and causing lineups at the gate. The delays then encourage drivers to just drop their trailers in the first available spot instead of where they've been instructed to put them.

A well-managed, YMS-enabled facility makes it possible for drivers to roll in, drop their load and move on, in the quickest possible timeframe. It will also help avoid driver detention fines imposed by carriers.

With the severe and worsening driver shortage affecting carriers' ability to deliver loads, it's no wonder they are increasingly requesting drop and hook programs. Enabling a driver to spend less time at the DC delivering his load means he is more productive for his employer and can make more money for himself.

Since carriers normally include a standardized amount of 'free' time before demurrage fees kick in, your YMS can build that in, and will be able to prioritize the trailers that need to be moved to avoid being charged. The YMS will also automatically notify carriers that their trailers are available, eliminating another touch point for your labour force.

If you cannot process third-party trailers quickly enough with your drop and hook program, you will end up paying charges for container dwell time. The worse the backlog, the more demurrage fees you'll end up forking over.

A YMS will provide visibility into when a dock is becoming available, and will notify the yard driver that a particular trailer needs to be moved there. Based on your business priorities, it will ensure the maximum throughput is achieved with minimum idle time.

If docks are sitting idle waiting for trailers, you are wasting valuable human and infrastructure resources, not to mention potentially delaying important outbound shipments, and impinging on warehouse operations.

Yard management can ensure that all resources are used to their optimum advantage and waste is minimized.

The lack of coordination combined with excessive trailer moves, demurrage charges and wasted labour are all adding up to increased costs for yard activities.

YMS can—and should—do:

That includes trucks, trailers and their contents, yard trucks and their drivers. Instantly know where each or all of your assets and inventory are with a click or a tap.

Managing yard drivers is the most costly part of your operation and is key to delivering service within your organization. With a YMS these dedicated drivers are equipped with a mobile device that transmits their next instruction. The moves planned by the YMS are optimized according to your business requirements to use the least resources and create maximum efficiency.

In order to get the best out of your assets, including the docks, and to maximize operational throughout, scheduling the docks should be a key part of the system. Both inbound and outbound loads can be managed this way, taking into account a custom rule set based on your business objectives and requirements.

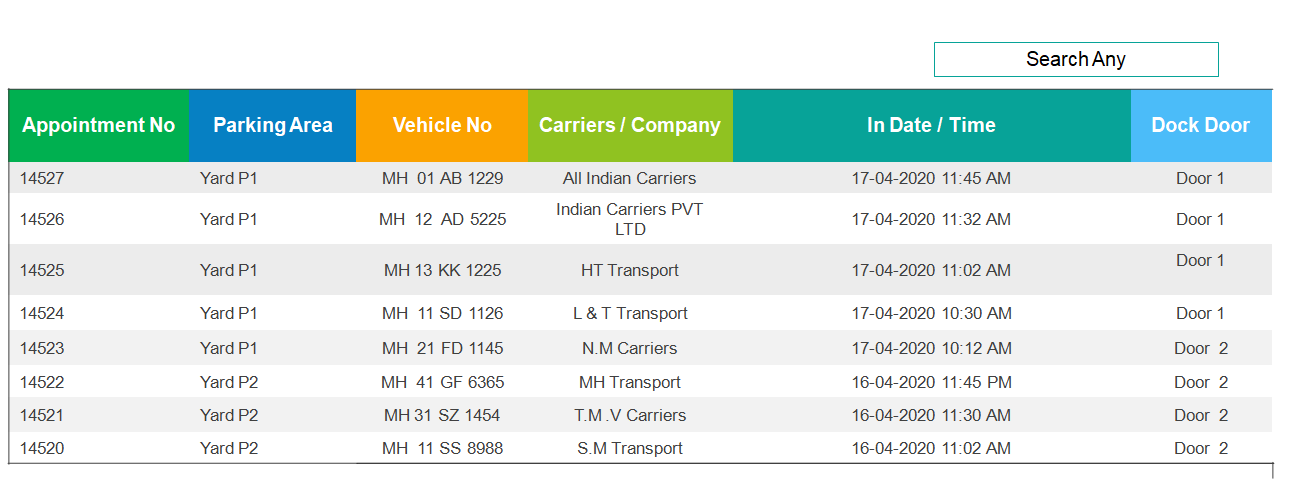

The YMS should be able to enhance gatehouse operations by streamlining the amount of time and effort it takes to check trucks and trailers in and out. As the gate is the first point of contact and the main security post for the facility, it's very important for the staff there to be able to quickly and easily identify each specific vehicle, why it's there and where it needs to go. Self-serve options for check-ins are a very useful tool for managing scheduled arrivals, and the YMS should offer this functionality.

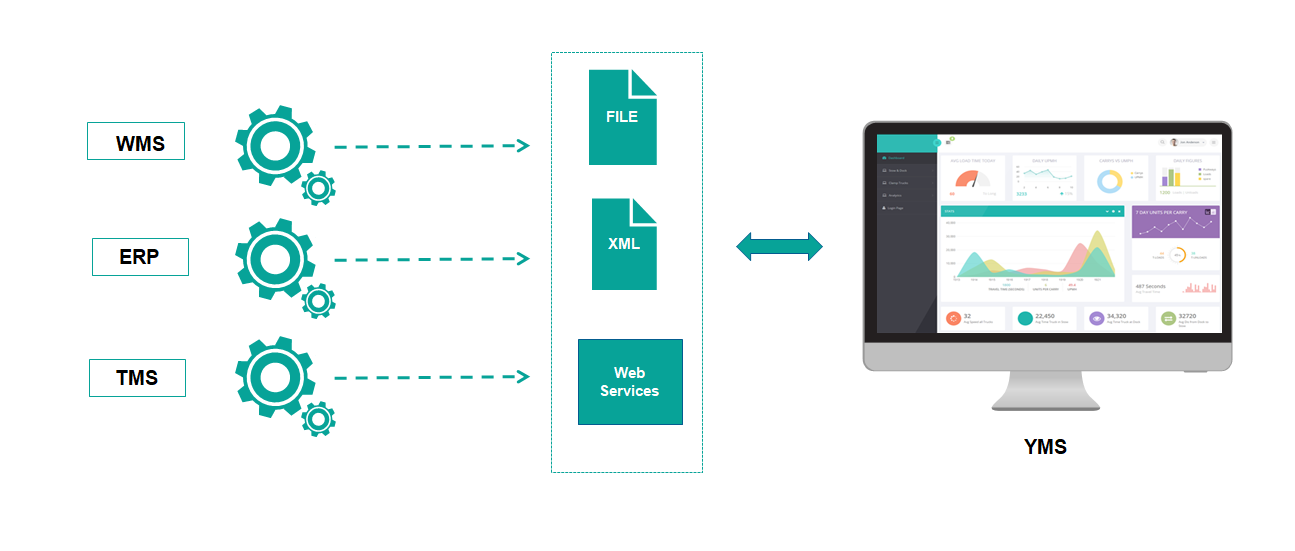

In order to maximize the value of your YMS it needs to be able to communicate with other systems, like your WMS and TMS, preferably through a standardized mode such as web services. This integration will eliminate the need for data re-entry and will ensure the continuity of the data contained in all the systems.

The YMS should be able to adjust priorities on a continual basis, responding to peaks and valleys in shipping and receiving volumes. It also needs to be able to forecast vehicle availability to respond to those fluctuating volumes

The system needs to perform as a control tower, wirelessly communicating instructions and critical information to all the yard drivers.

The YMS should be able to provide feedback on key indicators and metrics to allow management to gain insight into past performance that can be used to optimize yard and dock operations.

Manage the Gatehouse:

Integration with WMS, ERP, TMS:

YMS Architecture:

Yard Module:

A yard module basically operates as an extension of the WMS running your warehouse. It is designed to track the inventory on hand, in whatever storage medium you are using, whether it's racking inside or a container outside the four walls of the DC. It optimizes storage capacity utilization, manages the labour that is required for storing and accessing (picking, putaway, packing etc.) that inventory, and manages inbound and outbound orders.

Best-of-Breed Yard Management System:

A YMS is specifically designed to optimize labour and trailer resources and movements in the yard environment. Every yard is unique, so the system is designed with the ability to prioritize how trailers are handled at each site according to that yard's own needs. If one site needs to maximize labour productivity, the YMS can be tailored to do that. If another wants to emphasize inventory fill rates, that can be its overarching design objective. In addition to the eight tasks a YMS needs to be able to do, here are five additional points that distinguish it from a yard management module:

Solution Benefits:

Benefits of IOT enabled Yard Management